Sliding bearings. You understand what they are but are they suitable for your operations?

Let’s Slide into November with SBS’s handy sliding bearings guide!

Advantages of Sliding Bearings

What makes sliding bearings so good in the first place?

Sliding bearings, also known as plain or sleeve bearings, are suitable for a wide range of industrial applications. Their simple design with few moving parts provides ease of assembly and maintenance.

Sliding bearings feature strong load-bearing capacity and low friction coefficient, reducing energy losses and improving equipment efficiency. Additionally, a lack of rolling elements means smooth and quiet operation since there is minimal vibration or noise!

Self-lubricating bearings are highly beneficial as well, capable of operating under high-load and high-temperature conditions where rolling element bearings might fail. They are also more tolerant of contamination, and in most cases are more economical for heavy-duty or low-speed applications.

Disadvantages of Sliding Bearings

Everything sounds great! So, when would sliding bearings not work?

Sliding bearings are bound by friction as two surfaces (pin and bushing) slide and rub against each other. For better understanding of this concept, let’s explain with a simpler scenario. Moving your finger with light to minimal pressure over a tabletop is not harmful. However, if pressure is increased, this action will burn the skin.

With this knowledge in mind, the most important factor for sliding bearings is the PV-Value! The PV-Value indicates pressure or force in relation to velocity (Speed) and is crucial to understanding if sliding bearings are suitable for your operations. If the PV-Value required by your operations is higher than the bearing’s, the material will simply create too much heat from friction and bearing performance will be drastically reduced.

Still keen on sliding bearings, though?

At SBS, our technical engineers are capable in designing bushings considering these factors, while analysing premature bearing failure and advising room for improvement. We understand that designing a sliding bearing starts with consideration of operational requirements (pressure, speed) and environment.

Plain sliding bearings might not be an option, but custom solutions could do the trick!

What are the best industries for sliding bearings?

There is no ONE best operation for sliding bearings.

That’s the great thing about them: they’re versatile!

Sliding bearings can be found across many industries due to their ability to handle heavy loads, harsh and high-temperature environments. Their material is prescribed by the environment and type of application.

Here are just a couple industries you can find sliding bearings participating in.

Agriculture

In environments involving mud, dust and moisture, sliding bearings are an optimal choice due to high tolerances for heavy loads and shock!

From seeding and ploughing to fertiliser and harvesting machines, the options are endless. Sliding bearings enable more efficient equipment, extending life cycles.

Maintenance-free materials are also a great option for agricultural applications. The SBS COM-KU®/M, a maintenance-free solution, features a specially woven PTFE and synthetic fibre sliding layer. Boasting excellent mechanical properties and fatigue strength, this composite bearing’s extremely high load capacities makes it superbly suitable for various outrigger applications!

Construction

From managing movements within expansion joints to accommodating movement from thermal expansion, the role sliding bearings play in construction applications is significant.

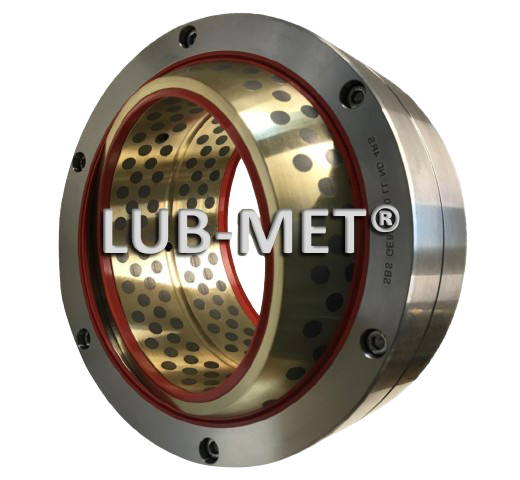

A couple great sliding bearing options from SBS is the FER-MET®, FER-MAS® bearing and the maintenance-free bronze material LUB-MET®!

The SBS FER-MET® and FER-MAS® are steel bearings extremely high load capacities. They are very wear-resistant and suitable for heavy operational demands with impact load. The LUB-MET® bearing is maintenance-free, manufactured from bronze and contains solid lubricant. Great for high operational demands, oscillating movements and very wear-resistant! The lubrication plugs help extend bearing life as most premature operational failures are caused by a lack of lubrication and grease.

The SBS Difference

Sliding bearings don’t just stop at agricultural and construction applications. You can find them in mining, hydropower, steel and marine/offshore operations!

SBS offers an extensive range of sliding bearings to meet your unique needs. With over 20 years of experience built on German engineering expertise and strong customer-centric values, we understand your frustrations and are here to assist every step of the way.

Don’t compromise with your sliding bearings, go with the best.

Email us today at info@sbs-bearings.com.sg for more information or call +65-6316 3850 to find out what we can do for you!