Mining

Downloads

Our Updated

Mining Catalogue

In our Catalogue you will find a wide range of bearings for Mining applications

Mining

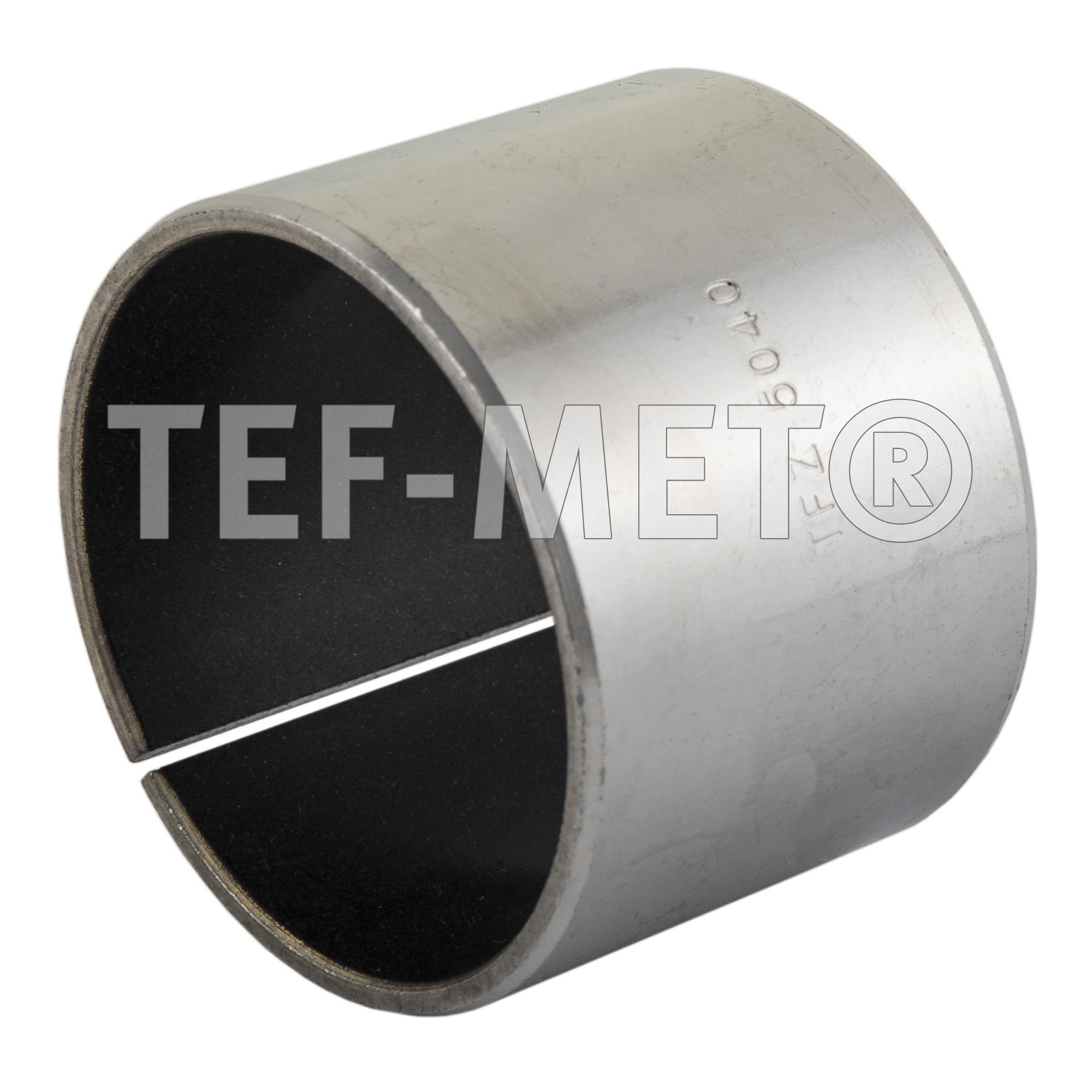

SBS offers an extensive range of sliding bearings for the Mining Industry

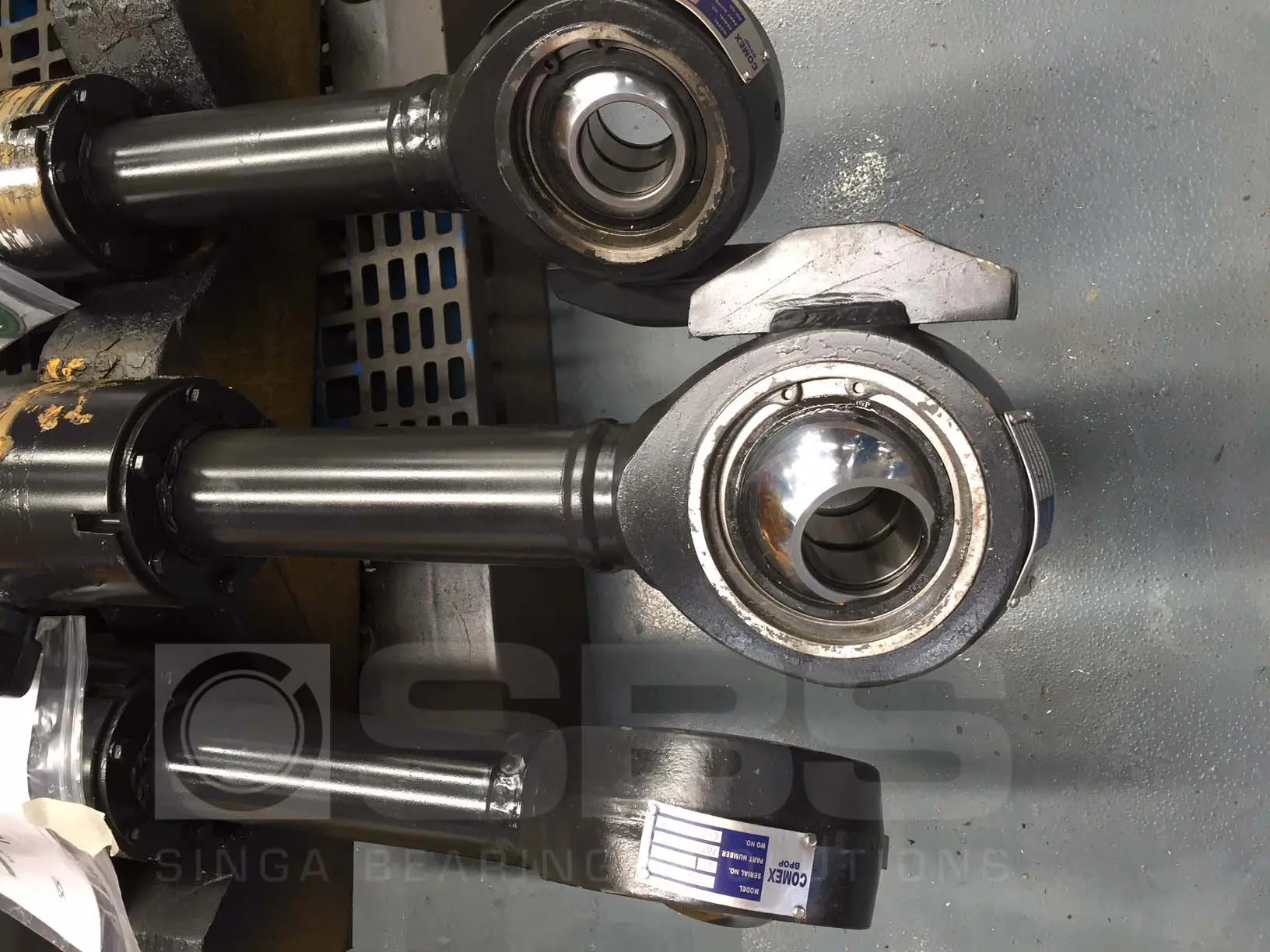

Many years ago SBS – Singa Bearings Solutions®Pte. Ltd. started to develop mining bearings that are comparable with OEM quality. With extensive material research and lab testings, we had gradually increased its range through actual life cycle testing in the mines with its mining contractors. SBS can be proud to say that our bearings often proved to work better with extended lifetime results. SBS’s track record had been commended by many clients with no reports of bearing failures during operations.

SBS also prides itself to come up with bearing solutions with change of materials or a complete re-design of genuine bearings if they prematurely fail, causing unnecessary and expensive downtime to the operator. This kind of major bearing failures tend to happen to the bucket and H-Link attachment and especially if oversized buckets are being used. Dozer Idler bearings often seem to fail through the extensive contamination of mud creeping between shaft and bushing, causing early wear.

SBS also started to develop more complex and multi parts arrangements like the Pin Boogie for the under carriage of larger Dozers and moving further into the development of under carriage spring coils.

For parts development and special enquiries, kindly email to info@sbs-bearings.com.sg

For our standard mining parts, please download our Mining Bearings Catalogue.