Agriculture

Downloads

Our Updated

General Catalogue

In our Catalogue you will find a wide range of bearings for Agriculture applications.

Agriculture

The Agriculture industry is a highly diverse market sector with multiple different challenges and requirements.

From forestry machines to seeding and ploughing, to harvesting and fertiliser machines, the market leaders are designing bigger and/or more efficient automated equipment. Therefore, the demands on the bearing are subsequently increasing steadily to cope with higher loads and impacts, extended life cycles and the need for maintenance-free materials.

SBS is not only equipped with the engineering knowledge and experience to provide the right bearing materials for the specific machine, but also to assist with the development of new high-performance equipment. Through our long experience working with several world leading OEMs, SBS has been involved in the development of new sliding pairings and applying different coating technologies especially for steel/ steel pairing, to deliver best results for earth digging and ploughing.

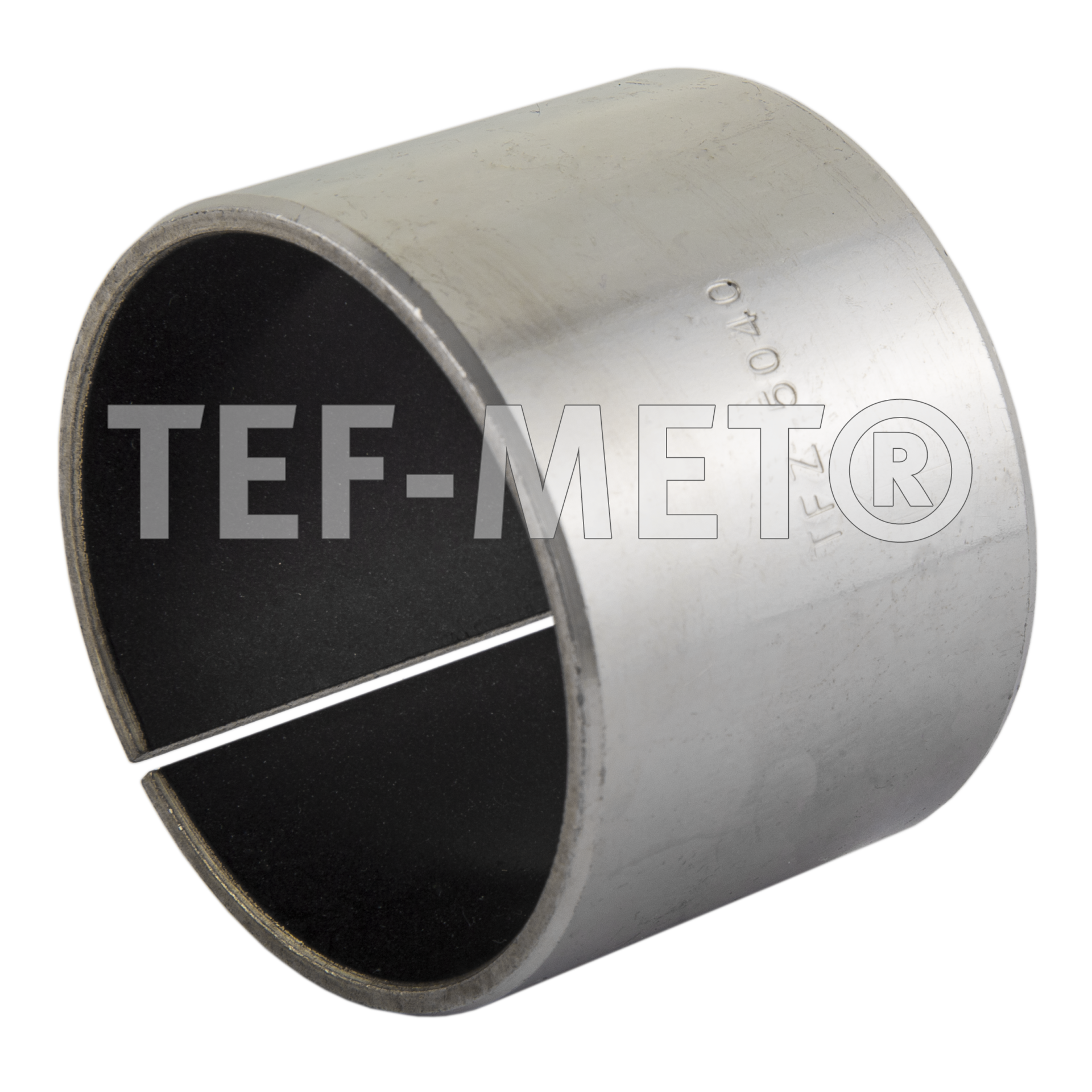

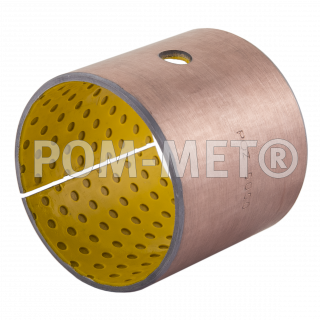

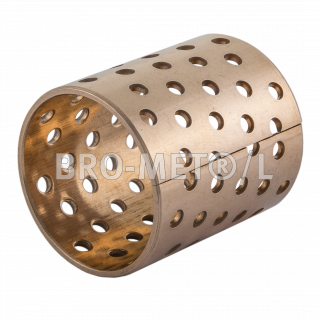

SBS was also a pioneer in introducing the COM-KU®/M as a maintenance-free solution with its extremely high load capacities for various outrigger applications, e.g. long reach grass cutting outriggers. Other frequently used materials are materials from the

BRO-MET® and BIV-MET® family, POM-MET® and BRO-MAS® as well as LUB-MET®.