Construction

Downloads

Our Updated

General Catalogue

In our Catalogue you will find a wide range of bearings for Construction applications.

Construction

The construction Industry has two major segments for SBS Bearings.

One segment consists of heavy equipment like tower cranes, cement mixers, excavators, that require bushings in their hinges, hydraulic cylinders, undercarriage and suspensions. The other segment is the construction itself, being a building, industrial plant or a bridge for instance.

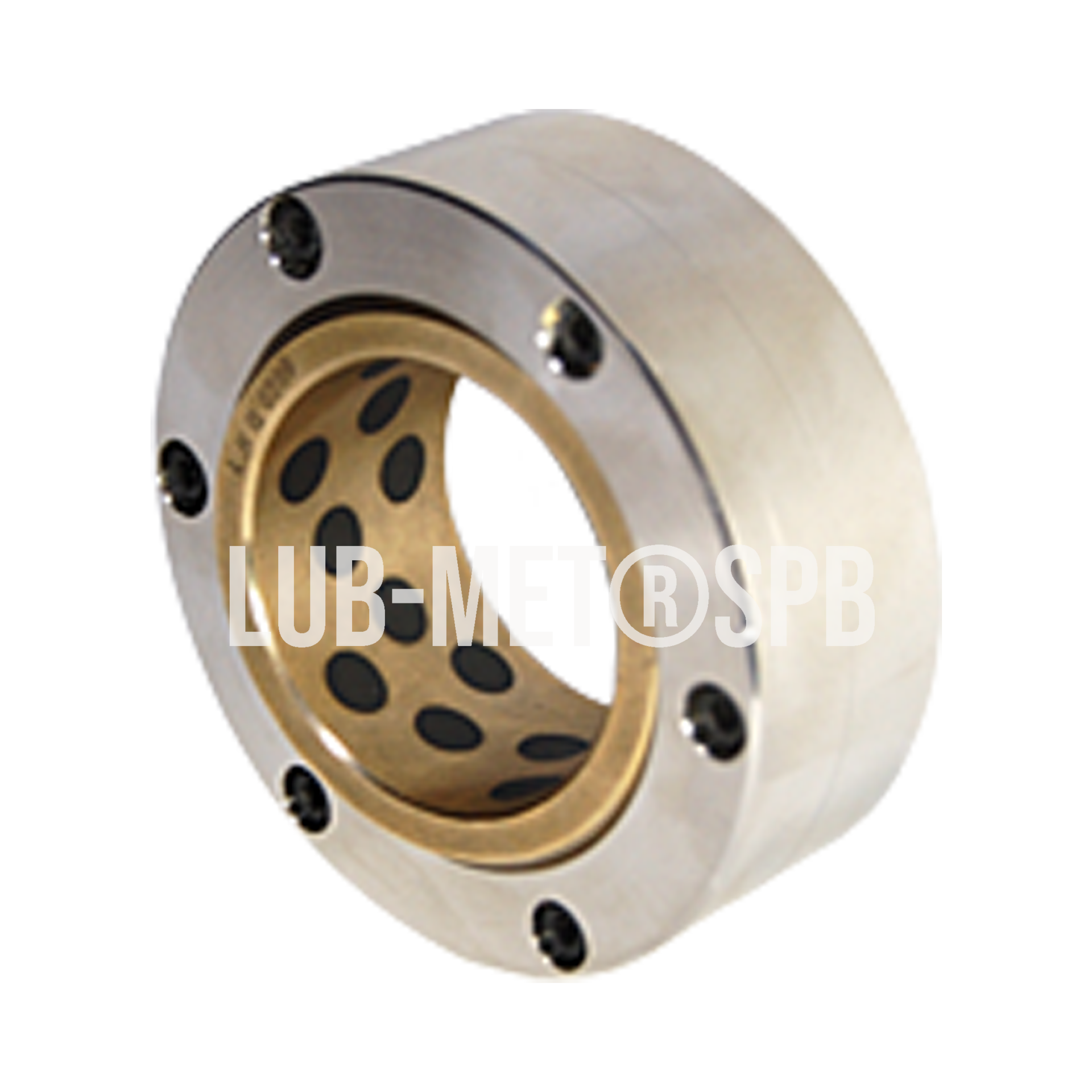

The latter is a very interesting one and it is a niche market for SBS. Big buildings and structures need moveable joints within the facade or connections e.g. like a bridge to prevent the structure from being too rigid, allowing it to “micro-move”. Thermal expansion (winter/ summer), strong winds, vibrations and earthquakes can cause a severe damage to an inflexible structure. A good example is one of SBS’s projects in Singapore: our COM-KU®/D plates with a mirror polished stainless-steel counter surface were chosen for the connecting 3-storey high link bridge between the two towers of the Marina One’s Skyscraper. In this instance, the product application allows one side of the bridge/ tower connection to move “in and out” of the building.

In addition, SBS’s self-aligning support bearings also help to equalise small height differences during construction and installation of long beam structures like bridges or roof arches. They consist of a concave steel base with a perfectly fitting convex calotte for the self-aligning purpose. The calotte features a sliding plate, that can be customised to the environmental conditions, with a mirror finished top plate, which is normally welded onto the structure. It guarantees for effortless installation and performance.