What are Sliding Bearings?

Sliding bearings are engineered with the intention of decreasing friction between two moving parts. This is done by offering a smooth surface for relative motion.

It is the simplest type of bearing, consisting solely of a bearing surface with no rolling components. These bearings are frequently chosen for applications demanding stability, low maintenance and high load-bearing capacity.

SBS – Singa Bearings Solutions specialises in quality sliding bearings, designed with invaluable German technological expertise and knowledge. With a large range of materials, we cater to a wide variety of applications and are able to target specific needs.

Let’s explore where SBS sliding bearings can be found!

Sliding Bearings on Ground

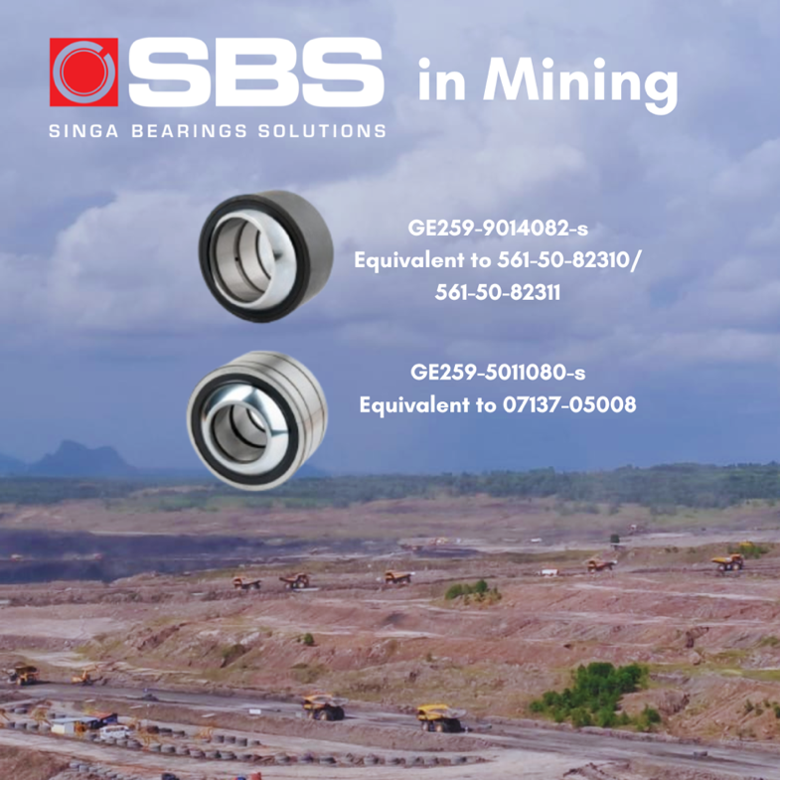

SBS sliding bearings can be seen in the mining industry.

With the ability to sustain low maintenance costs and longer bearing service life in comparison to alternative options, they are a popular choice!

SBS first started developing mining bearings with the assurance that they were comparable with OEM quality. Through immense material research and lab testing, we have persistently increased our range through hands-on life cycle mine testing in collaboration with mining contractors, maintaining this quality.

To this day, SBS mining bearings continue featuring extended lifetimes and client commendations reporting no bearing failures during operations!

Some bearing applications that SBS sliding bearings can be found in are excavators, dozers, dump trucks and graders.

SBS bearings are also involved in construction.

Sliding bearings can be found in heavy equipment such as tower cranes and cement mixers. These machinery require bushings in their hinges, hydraulic cylinders, undercarriage and suspensions.

Suitable SBS materials for sliding bearings in the construction industry include TEF-MET®, LUB-MET® and COM-KU®/D.

SBS is also equipped to address issues in the Agricultural industry.

From forestry machines to harvesting, fertilising and more, the agriculture industry calls for increasing efficiency and automation. Sliding bearings are vital to manage high loads and impacts, lengthened life cycles and maintenance-free conditions!

The SBS team has had vast experience collaborating with several global-leading OEMs. This has provided us crucial knowledge in suggesting and providing suitable materials, developing new sliding bearings and implementing the best results.

We are proud to be a pioneer in introducing the COM-KU®/M, a maintenance-free solution with exceedingly high load capacities for various outrigger applications.

Other suitable materials include our TEF-MET®, BRO-MET®, POM-MET®, as seen below!

Sliding Bearings On Water

SBS offers an extensive range of sliding bearings for the Marine/Offshore Industry.

Holding numerous track records, we are trusted to provide quality maintenance-free and/or corrosion-free solutions. Over our 20 years in the industry, we have conducted meaningful inspections by gaining access to shipyards, increasing and refining our proficiency. Through time, we have accurately identified numerous bearing solutions.

SBS is also highly reputable in the hydropower industry!

We have delivered LUB-MET®, GAP-MET®/B & GAP-MET®/N bearings for multiple turbine overhauls in South East Asia (SEA), also supplying these materials and our COM-KU®/D products to world leading OEM builders.

For more information on these products, click here: https://sbs-bearings.com/wp-content/uploads/2025/04/SBS-General-Catalogue-2025.pdf

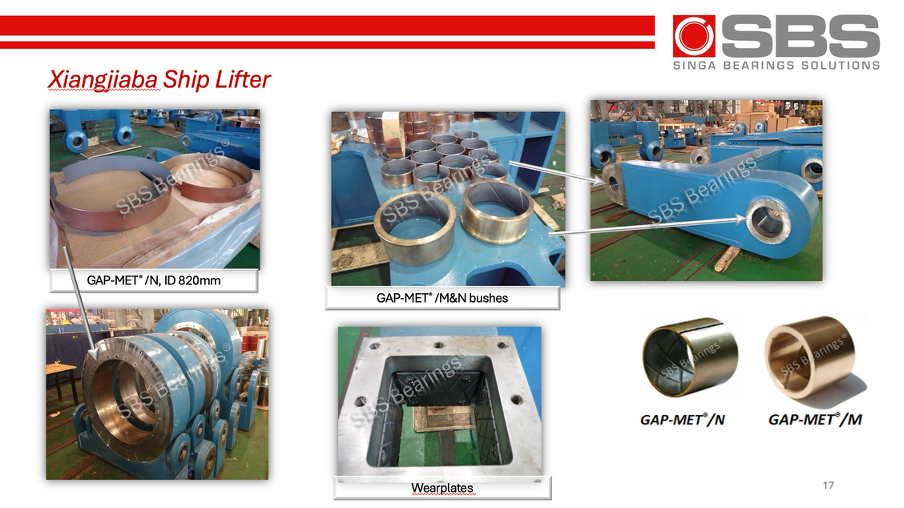

As a true expert in this field, the SBS team has featured in major projects. This included supplying around 2,000pcs of GAP-MET® bushings for the second largest Ship Lifter in the world at the Xiang Jia Ba Dam.

SBS’s strengths are also shown through the construction of large-sized LUB-MET® Spherical Plain Bearings (SPB) ranging from 400 – 800mm ID. Our biggest achievement was fulfilling our client, in a short lead time, six heavy duty bearings with ID of 1000mm, OD of 1450mm and weighing 4.7 tons per piece..

Sliding bearings are particularly useful in water-based environments as they have the ability operate as a lubricant. Thus, diminishing oil reliance and promoting beneficial environmental impact!

How can SBS help you?

Here at SBS, we are dedicated to finding the right materials and solutions for you.

With a cohesive, expert team, we understand how to get you where you need to be. We realise that bearing issues need solutions thought of both quantitatively and qualitatively and we place emphasis on building meaningful, long-lasting relationships with our customers. SBS is dedicated to providing sophisticated solutions with innovative insights and designs driven by our German engineering roots.

From Ground to Water, we are ready to address your needs and assist wherever possible.

‘Bearing’ the weight in your project? Let us ‘bear’ it with you!

Contact the SBS team today at info@sbs-bearings.com.sg or call us at +65-6316 3850!

To read more about our past achievements and future goals, click here! https://sbs-bearings.com/blog