Here at SBS – Singa Bearings Solutions® Pte. Ltd., we recognize ourselves globally as a leader in sliding bearings technology. SBS Bearings provide a comprehensive range of plain bearings designed to enhance the service life of industrial machinery. SBS continuously strives on tribological standards and innovations to fulfil our customers’ needs. Our products are engineered for maintenance-free operation, providing low friction and low wear characteristics essential for high-performance applications. SBS Bearings provide over 30 types of materials for our sliding bearings, thrust washers and wear plates.

What are Sliding Bearings or Plain Bearings?

Sliding bearings are also known as plain bearings or journal bearings. Unlike their cousin, the roller bearings, they do not utilize balls or rollers. Sliding bearings or plain bearings are mechanical components that rely on a sliding interface, often lubricated to reduce friction and wear, for a smooth operation. Sliding bearings or plain bearings are often used in heavy equipment with high loads and low speeds.

Types of Sliding Bearings or Plain Bearings and which applications are they used for?

Sliding bearings or Plain Bearings can be created from a variety of materials depending on one’s needs and wants. These include bronze, aluminium alloys, stainless steel, plastics, fiber-reinforced composites and more. Some sliding bearings or plain bearings are designed with self-lubricated material like PTFE or graphite plugs, making them maintenance-free. Some sliding bearings or Plain bearings or bushings that require maintenance, have grease pockets to contain lubricants for a smoother operation. They are also widely known for their simplistic design and low noise operation in specific applications. Sliding Bearings or Plain Bearings can be used for a variety of applications for industries such as Mining, Hydropower, Marine/ Offshore, Agriculture, Construction, Steel, Renewable energy such as Offshore Wind Farming, Wind Turbines and more!

SBS’s key products

SBS’s extensive product lineup includes various types of sliding bearings / plain bearings, thrust washers and wear plates, are tailored to meet everyone’s and anyone’s diverse technical applications:

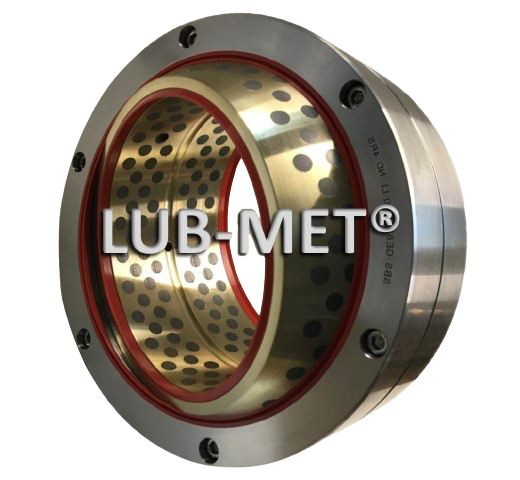

- LUB-MET®: These maintenance-free bearings incorporate graphite plugs as solid lubricants, eliminating the need for additional grease or oil lubrication. They are particularly suitable for high-load applications where durability and reliability are critical. These bearings are best suitable for movements which occur only in long intervals as the LUB-MET® / stainless steel combination guarantees a faultless and long-term functionality of the bearings. This type of sliding bearing or plain spherical bearing are suited for many types of applications for Marine and Offshore, Mining, Agriculture, Steel Plants, Injection Molding and Hydropower.

- COM-KU®/D: Featuring a stainless steel outer ring and a COM-KU®/D sliding layer, these spherical plain bearings offer high load capacity (especially for impact and edge loads) and are compatible with all DIN spherical plain bearings. Their maintenance-free design ensures long service life without the need for lubrication. For higher requirements such as higher temperature ranges, different materials are available in this category. This type of sliding bearing or plain spherical bearings are suited for many types of applications for Marine and Offshore, Mining and Renewable Energy and Construction.

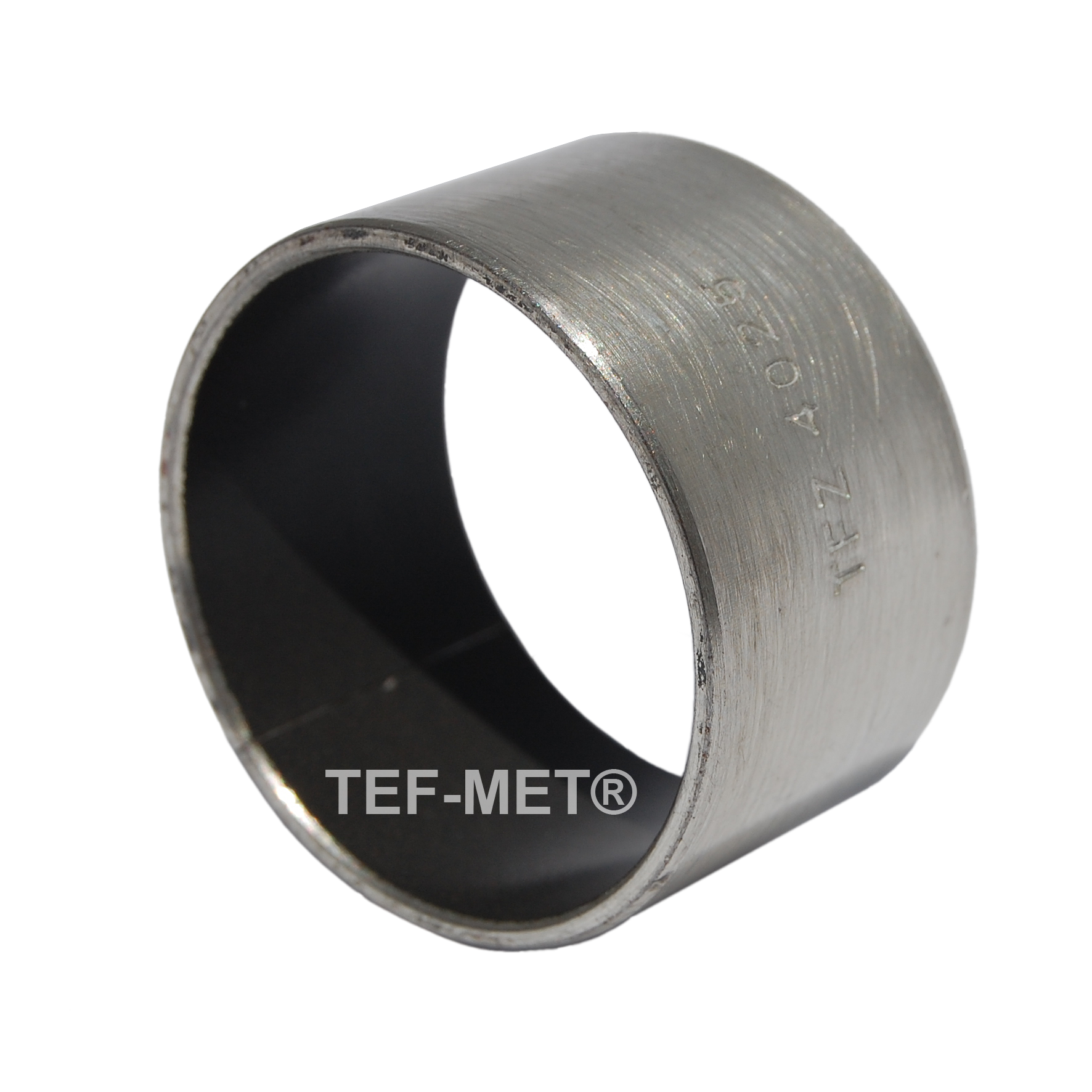

- TEF-MET®: This wrapped composite sliding bearing combines a steel backing with a PTFE sliding layer, resulting in outstanding sliding and wear performance. TEF-MET® bearings are maintenance-free, possess high load capacity, and are versatile across various applications. Grease lubrication of the outer surface may be necessary when mounting and special dimensions are available upon request. This type of sliding bearing or plain bearings are suited for many types of applications for Agriculture, Construction, Mining and Injection Molding.

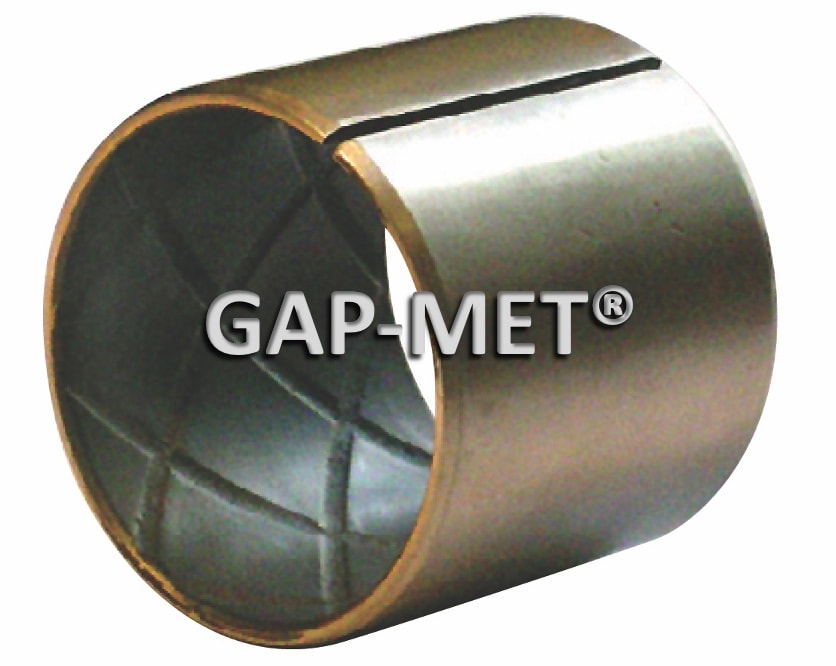

- GAP-MET®: Utilizing a sintering technique, these self-lubricating bronze sliding bearings incorporate graphite powder within their matrix. The GAP-MET® series offers high load capacities and temperature resistance, making them very suitable for demanding industrial environments. For higher requirements (e.g. higher temperature ranges), different materials are available for this category. This type of sliding bearing or plain bearings are suited for many types of applications for Agriculture, Hydropower and Steel Plants.

Advantages of SBS Bearings

Our sliding bearings offer a vast array of advantages that make them the preferred choice for various industrial applications:

- Maintenance-Free Operation: The incorporation of self-lubricating materials such as PTFE and graphite eliminates the need for additional lubrication with grease or oil, reducing maintenance requirements and downtime. This makes it more convenient overall.

- Low Friction and Wear: The advanced materials used in our bearings provide low friction coefficients and minimal wear, enhancing the efficiency and longevity of machinery components. This means less downtime for our customers.

- High Load Capacity: Engineered to withstand high radial and axial loads, our bearings ensure reliable performance under demanding conditions.

- Temperature and Corrosion Resistance: Our bearings are designed to perform effectively across a wide temperature range and in corrosive environments, making them suitable for applications involving exposure to water, chemicals, and extreme temperatures. At SBS, we provide bearings suited to your every need.

Technical Support and Resources

We are committed to providing exceptional technical support and resources to assist clients in selecting the most suitable bearing solutions for their applications. Comprehensive data sheets and product information are available in PDF format on our website, offering detailed specifications, material properties, and mounting advice. Clients can access these resources to make informed decisions and ensure optimal performance of their machinery.

For personalized assistance, clients can contact us via email or through the contact information provided on our website. Our team of technical experts is dedicated to delivering high-quality service and support, ensuring that clients receive the optimal possible solutions tailored to their specific requirements.

In addition to our standard product offerings, we have the capability to produce special items in various materials, including bronze, to meet unique application needs. This flexibility allows us to cater to a wide range of industries and applications, providing customized solutions that enhance the performance and reliability of machinery components.

Excellent Quality and Customer Service

By choosing SBS – Singa Bearings Solutions® Pte. Ltd., clients benefit from decades of expertise, high-quality products, and a commitment to innovation and customer satisfaction.

What are SBS’s current core values and has this changed over time?

SBS – Singa Bearings Solutions Pte Ltd values customer focus, quality, innovation, and integrity. Our core emphasis on delivering high-quality products and services, along with ethical practices and a customer-centric approach, has remained consistent. https://sbs-bearings.com/blog/fearless-leadership-wins-that-have-stood-the-test-of-time

- Quality:

SBS emphasizes attention to detail and high standards, as evidenced by our ISO 9001:2015 certification.

- Innovation:

SBS sees innovation as crucial for staying competitive and meeting evolving customer needs.

- Integrity:

SBS aims to build trust by acting with integrity at all times and treating people fairly and respectfully.

- Evolution:

While specific wording may adapt over time, the overarching values of prioritizing customer needs, delivering high-quality products, and maintaining integrity are long-standing.

The SBS Team has definitely expanded in the last 20 years!

How has this affected operations and what does SBS Bearings do to keep up team morale?

Our focus stems from constantly improving productivity and efficiency for our customers. Our engineering, manufacturing, sales, marketing and after-sales team function cohesively, providing flexible, worthwhile solutions managing varying complexity levels.

LINK TO https://sbs-bearings.com/blog/the-rewards-of-an-engaged-workforce

“We believe in cultivating a working environment that ignites employees with enthusiasm, empowers them to break through conventional frameworks of thinking to address how we can better serve our customers,” describes Judy Hallauer.

The SBS’s O.N.E. culture characterises the working environment operations in Singapore has seen continual successes of collaboration

O pen and Respectful communications

N othing is impossible! mindset

E volving for better, both professionally and personally

20 Years of Experience Sliding Bearings / Plain Bearings, Thrust Washers and Wear Plates

Over the past 20 years, SBS Bearings has focused on quality and reliability, evolving its product offerings to meet the demands of various industries, particularly Mining. SBS has expanded our product range, developed new materials and designs, and implemented innovative solutions for bearing failures.

Read more here: https://sbs-bearings.com/blog/sbs-bearings-20-years-of-customer-driven-excellence#more-9851

For the next 20 years, we expect further advancements in materials, designs, and integration of smart technologies, focusing on longevity, efficiency, and sustainability.