Hydropower

Downloads

Our Updated

General Catalogue

In our Catalogue you will find a wide range of bearings for Hydropower applications.

Hydropower

SBS – Singa Bearings Solutions Pte Ltd (SBS) is highly reputable in the Hydro Power and Hydromechanical sector .

Our extensive projects are related to turbine technology for overhauls and new builds. On the hydromechanical side our expertise relates to Dam Gates, Barrages and Sluices as well as Moveable Bridges.

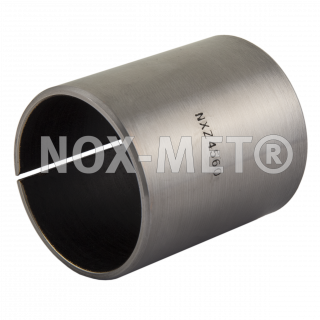

SBS had delivered its LUB-MET®, GAP-MET®/B & GAP-MET®/N for numerous turbine overhauls in South East Asia (SEA) as well as supplying these materials and our COM-KU®/D products to world leading OEM builders. On many occasions, our engineering expertise was required by clients to upgrade old turbines with up-to-date bearing technologies.

As an expertise in this field, SBS has several track records, featuring major projects such as supplying almost 2,000pcs of GAP-MET® bushings for the second largest Ship Lifter in the world at the Xiang Jia Ba Dam, with several 600 and 800mm diameter bushings and 4 massive ball joint with a 400mm diameter weighing 1.7 tons each.

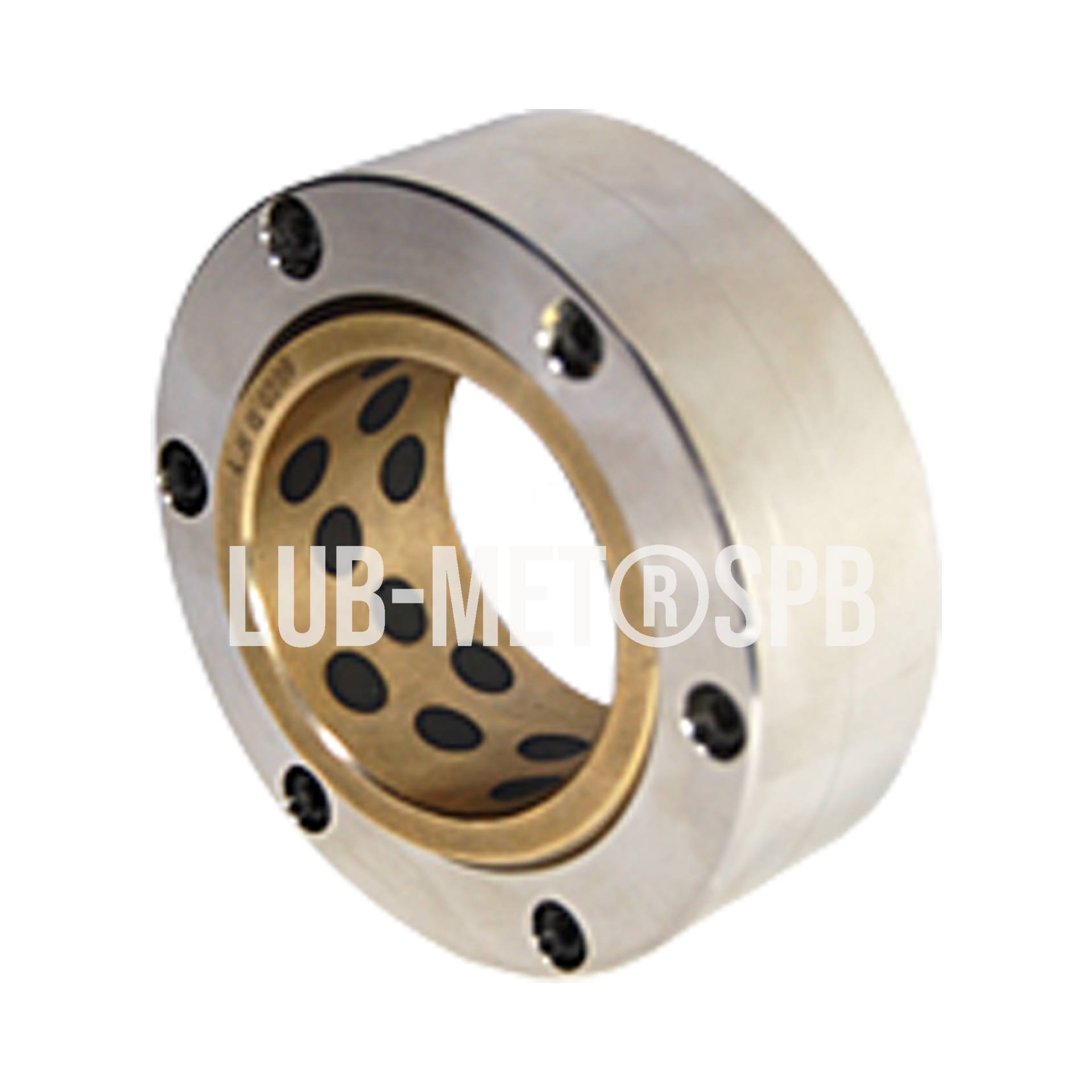

SBS’s key strength is in the construction design of large-sized LUB-MET® Spherical Plain Bearings (SPB) ranging from 400 – 800mm ID. Our biggest achievement was fulfilling our client, in a short lead time, six heavy duty bearings with ID of 1000mm, OD of 1450mm and weighing 4.7 tons per piece.

Often our clients also request to provide large sized stainless steel pins for major hydro mechanical projects. For the Nam Kong 3 Project, SBS manufactured not only the large size LUB-MET Spherical Plain Bearings, but also the related pins in hardened stainless steel.

With proven field tests, SBS has gained immense trust from our clients over the years. This has led us to be not only a supplier but a partner, as well as being their reliable consultant for their technical design, implementing the most feasible bearings.